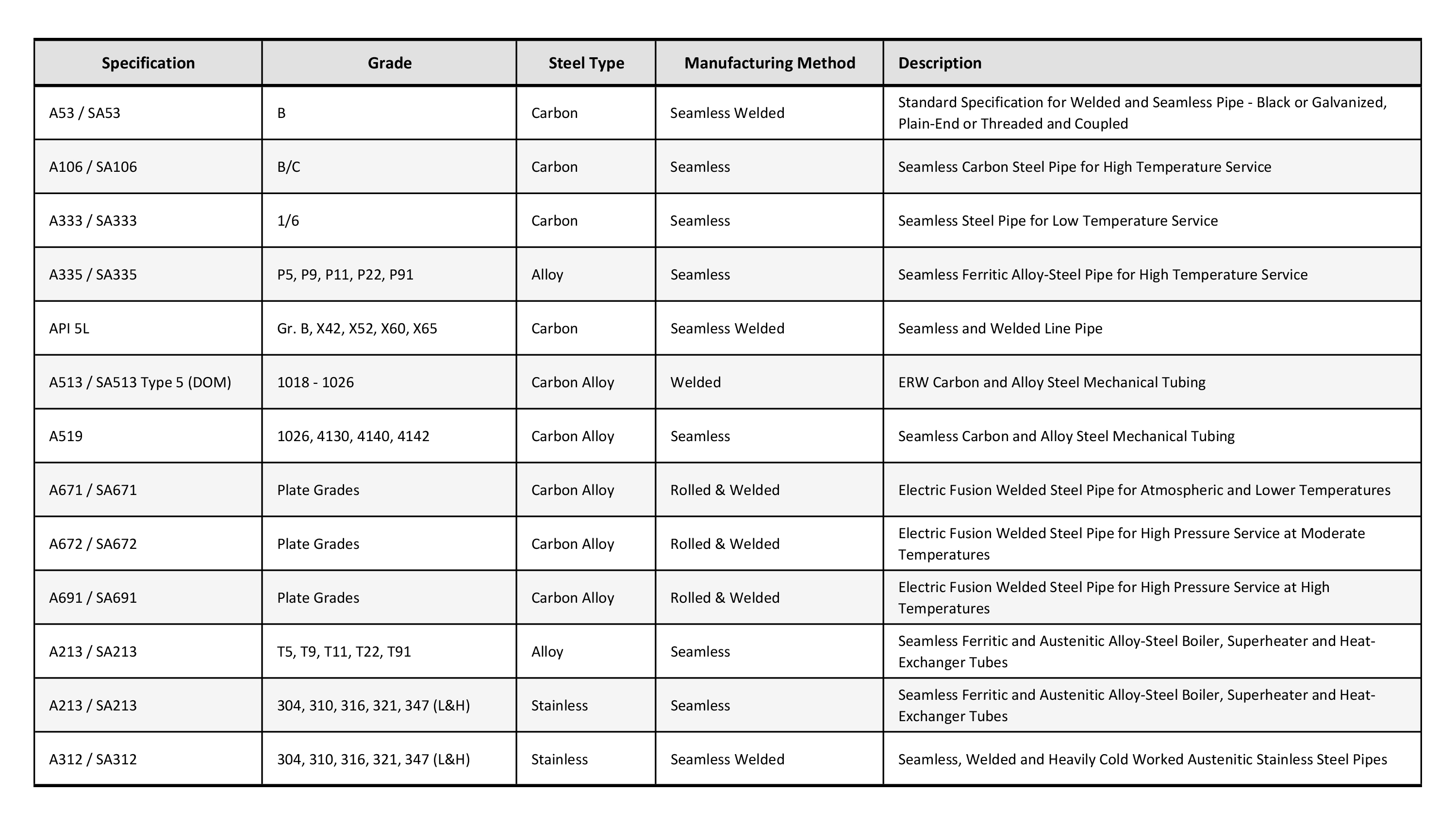

U.S. Steel Pipe offers a wide range of material and specifications covering carbon, alloy and stainless steel in pipe, tube, fittings and flanges. Our real-time inventory management, full mill documentation and continuous quality control make your project procurements smoother and more cost-effective :

Common Material Specifications We Offer

Pipe Sizes. Federal Steel Supply provides a pipe chart for sizes of steel pipe 1/8” nominal to 48” Outside Diameter that illustrates nominal Pipe Size and Scheduled Walls as compared to actual outside diameter, wall thickness and weight/ft. The left side of the pipe chart indicates the difference between the nominal and actual size. Nominal sizes 1/8” through 12” are different from the actual outside diameter sizes (much like a 2 x 4 is not really 2 inches by 4inches). In sizes greater than 14”, the nominal size is the same as the measured O.D. size.

Wall Thickness : AISI Pipe Schedule Numbers (5-XXH) correspond to the most widely recognized and produced wall thicknesses of steel pipe (not tube). Schedule numbers include; 5, 10, 20, 30, 40, STD, 60, 80, XH, 100, 120, 140, 160, XXH. These “schedules” refer to a specific wall thickness in inches corresponding to a specific O.D. size in inches. Please note schedule 40 (Sch 40) and standard (Std) are the same wall thickness through 10" Pipe Size, while Sch 80 and XH are the same wall thickness through 8” Pipe Size. Actual wall thickness are always written as “Decimal Parts" of an inch and are written to three decimal places (example: one inch wall is written 1.000”). The method of manufacture and sizes described limit the wall thickness that can be produced. (Hence a 4 ½” O.D. pipe could not have a 3.000” wall.) Please review our pipe chart for more detail.

Commonly produced wall thickness for various methods of manufacture are as follows :

Federal Steel Supply specializes in Heavy-Wall pipe and carries heavier than Scheduled Wall thicknesses.

While many other wall thickness can be manufactured by a mill somewhere in the world, any thickness that is not on the pipe chart is considered an "Unscheduled Wall” and would normally be available by special order.

Federal Steel Supply has extensive experience in providing machining services to achieve exact wall thickness tolerances or to meet minimum ID/OD requirements.

As the engineering designs become more involved and the end use more critical the demand has increased for material with a guaranteed “minimum wall thickness”. Generally on 24” O.D. pipe and under, manufacturer tolerances are stated as +/- 12.5% the nominal wall thickness. Therefore, minimum wall thickness can usually be calculated as 12.5% under the average or nominal wall thickness. For example, 2.500” nominal wall would approximate 2.188” min wall. Depending on the application, Tubing specifications normally have much tighter wall tolerances than Pipe specifications. Pipe can also be machined to achieve more exact wall thicknesses or minimum ID requirments.

*Widely recognized specification writers for Pipe, Tube, Fittings and Flanges include ASTM, ASME, API, NACE, AWWA, ABS, Mil-S, ANSI, AISI. ASTM (American Society Testing and Materials) develops international standards for materials, products, systems and services used in construction, manufacturing and transportation.

ASTM specifications are usually designated by the letter A followed by a number (ex. A-106). ASME (American Society Mechanical Engineers) is one of the oldest standards developing organizations in the world. The ASME Boiler and Pressure Vessel Code is commonly used to outline the design, fabrication and inspection of boilers and pressure vessels. ASME spec’s are designated by the letters SA followed by a number (ex. SA-106). API (The American Petroleum Institute) is the only national trade association that represents all aspects of America’s oil and natural gas industry.

In this capacity, API develops standards for many products (including Pipe and Tube) used in the Oil and Gas industry. API spec’s are usually designated by the letters API followed by the specification identifier (ex. API 5L). NACE International is a global organizatoin focused on improvements in corrosion protections and is a standards-writing organization accredited by the American National Standards Institute (ANSI) (ex. NACE MR0175). AWWA (American Water Works Association) standards provide minimum requirements for design, installation, performance, and manufacture of products used in water treatment and supply.

AWWA spec's are designated by the letters AWWA followed by the specification number. (ex. AWWA C200). Other specification writers that may have specifications for the use of Pipe, Tube Fittings and Flanges are : ABS (American Bureau of Shipping), Mil-T and Mil-S (U.S. Military), ANSI (American National Standards Institute) and AISI (American Iron and Steel Institute).